System Design and Simulation

Section outline

-

-

Hello and welcome to the HyCool course System design and simulation.

This course provides basic information and knowledge on overall system design and simulations of thermal energetic systems. Furthermore, this course includes three tests for you to check your skills on latent heat storages and dynamic calculations. The course is structured in 6 different topics:

- Topic 1: Simulation fact sheet

- Topic 2: System simulation example

- Topic 3: Short simulation video

- Topic 4: Online tests and simulation exercises

- Topic 5: HyCool Pre-feasibility simulator

- Topic 6: HyCool EER Calculator Tool

-

-

-

System simulation fact sheet

To estimate the performance of a complex thermal system, such as the HyCool system, a dynamic simulation is an excellent possibility for investigation. The systems’ performance is affected by various aspects, not only by outer parameters, but also by inner parameters. For example, the weather, more precisely the ambient temperature, has an impact on the rate of cooling of a hybrid chiller, which then again affects further circuits and elements in the system, e.g. the compression chillers. Understanding the total system and its single factors and their function within the system is necessary for a reliable simulation.

An important criterion in the simulation is the representing of the solar thermal plant, in fact the Fresnel collector plant. As Fresnel collectors operate very differently compared to flat solar thermal collectors, the most realistic simulation is both important and complex to run. Before a simulation is going to be displayed in an appropriate programme, a first analysis has to be conducted. On the one hand, this analysis is to render the results of the simulation. Simulations can aim on different aspects of a system, such as thermal energy, electric energy, intermediate results or final results. On the other hand, the analysis is required to identify the relevant elements of the system in order to gain information of the simulation targets; these might be solar thermal collectors and thermal storages or pumps and valves. This first analysis is necessary to focus only on system attributes which exert influences directly or indirectly on the simulation target.

Today, there is a wide variety of different simulation software programmes, offering individual advantages or disadvantages, based on your kind of simulation. Simulations can be held either staticly, using constant parameters, or dynamically, e.g. to run a simulation over a defined timeframe, such as a day or even a year.

The simulation for the HyCool thermal system was performed in TRNSYS 17 simulation programme. This computer software is able to display single characteristics like valves and pipes, but also technical and mathematical complex elements such as the chillers, thermal storages and an evaporation unit. Target of the simulation is the thermal performance, to say the chilling capacity of the adsorption chiller and the heat capacity and the rate of heating of the solar thermal collectors in combination with steam generation. By connecting the single elements of the system, in TRNSYS called “types”, user-defined information such as inlet-/ outlet temperature or flowrates can be exchanged between the types. Here it is to put focus on a correct connection of types, as the simulation programme does not inform or identify for wrong connection, as long as the connection does not lead to a numerical failure.

In the end, the understanding of both the observed system and the simulation programme is crucial for a realistic and correct system simulation. A simulation is only a modern and mathematical precise way to estimate a performance, the scientific, in the case of HyCool thermodynamic, background is the base of good simulation.

-

-

-

System simulation example

This example will give a short overview on how to build a simulation focussing on thermal-energetic performance. It shows the procedure from understanding a hydraulic scheme to finally developing a simulation deck and following performing of simulations.

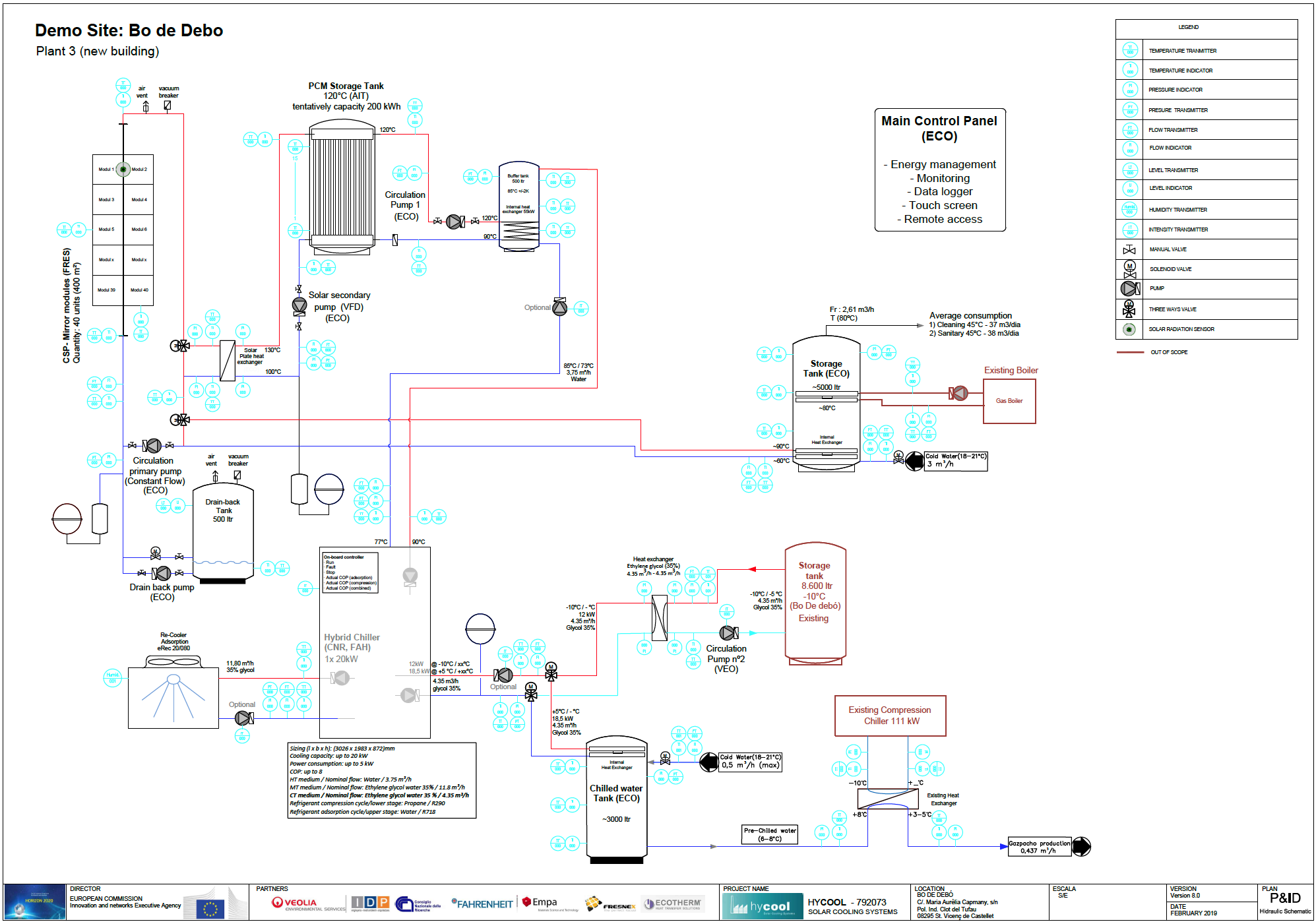

In figure 1, you can find the hydraulic scheme of the HyCool project, following the public “Deliverable 5.1 Drawing of the hydraulic schematic”. This scheme shows the interconnection of the individual elements within the solar cooling system. On the upper left corner, you find the display of the Fresnel Solar collector field. At the bottom of the schematic, you can find the display of the hybrid chiller composition, being connected to a cooler (left), a hot water tank (above) and the connection to the chilled water circuit. Within this hydraulic scheme, the desired flow rates, given in m3/hr, and temperatures of the heat transfer medium, given in °C, are described.

This hydraulic scheme will be integrated into the simulation software TRNSYS.

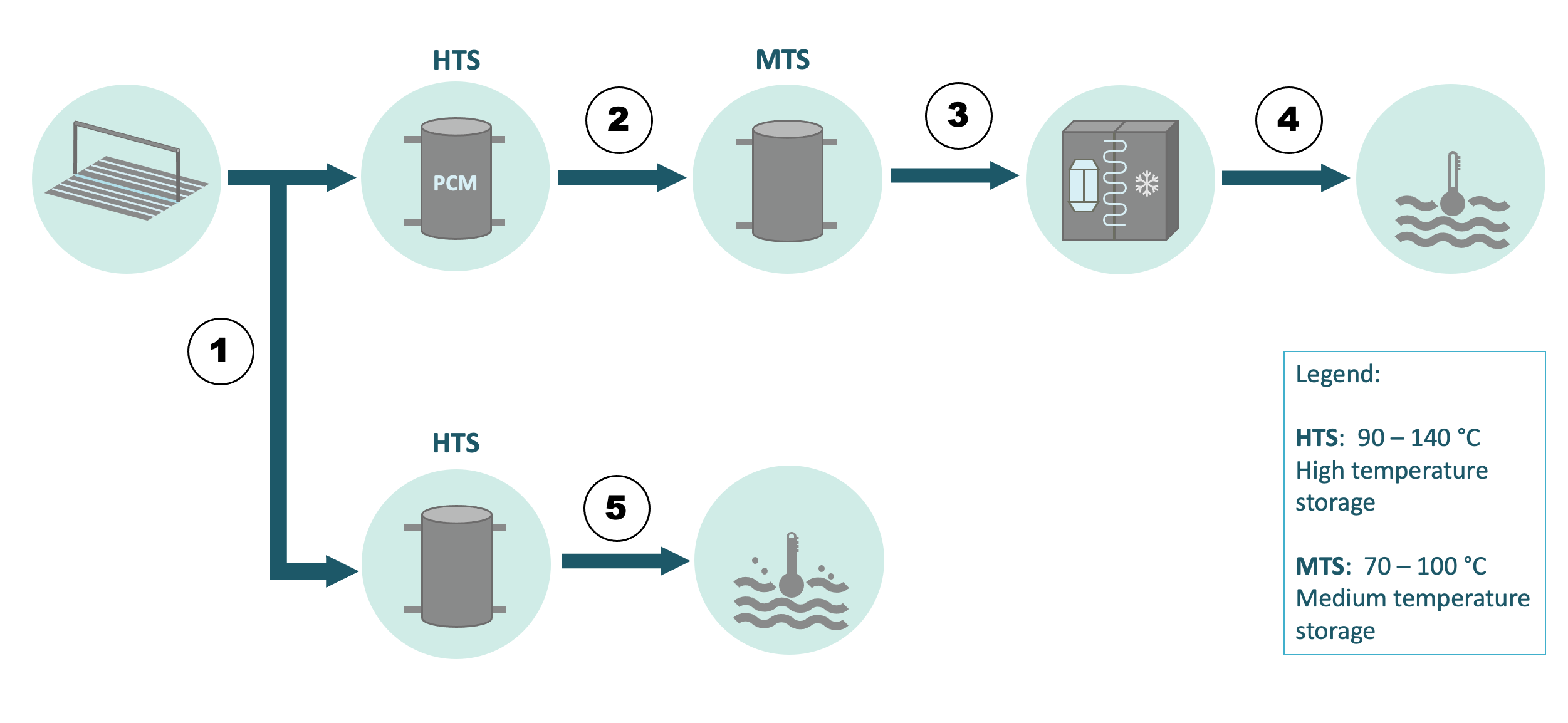

Figure 1: Hydraulic scheme of a HyCool solar cooling plant. (Source: HyCool project, Deliverable 5.1)The scheme below covers the previously described system in a simplified way. It shows the basic principle of the solar cooling system.

The principle is running by following steps:

- Distribution of heat from the solar collector plant primarily to the PCM storage. Once the PCM storage is full, further heat will be distributed to another storage for heating purpose (step 5).

- Distribution of heat from the PCM storage at high level (90- 140 °C) to the buffer tank at a lower heat level (70 – 100 °C).

- Distribution of heat from the buffer tank to the Hybrid Chiller. Heat is distributed at a level of 70 – 90 °C.

- Distribution of cold to the user.

- Distribution of heat to the user.

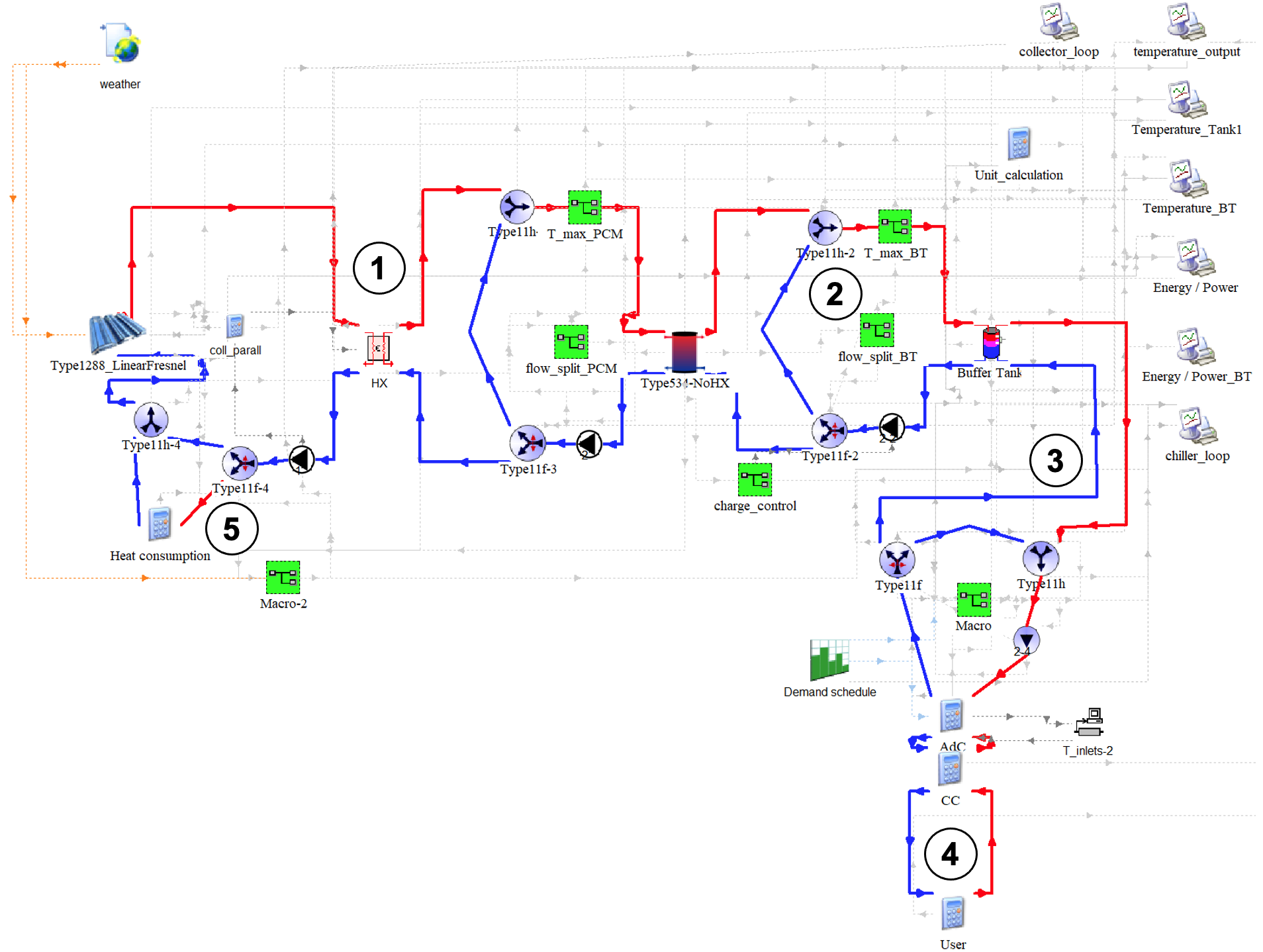

Figure 2: Simplified principle of the solar cooling plant. (Source: JER)Figure 3 shows the display of the solar cooling system within the simulation deck of TRNSYS simulation software.

TRNSYS simulation software models each component individually. The user is able to connect the single components with bonds, transferring information, such as flowrate, temperature or more simple signals such as “ON” or “OFF”.

The previous figure 2, showing the basic principle of the HyCool system for a plant, describes the system overall in 5 steps. In figure 3, these steps are given in the simulation deck for a better understanding. The goal of this simulation is the examination on the thermal energetic performance of the system throughout the course of a year.

Figure 3: Overview of the TRNSYS simulation deck, representing the HyCool solar cooling plant. (Source: JER)

- Distribution of heat from the solar collector plant primarily to the PCM storage. Once the PCM storage is full, further heat will be distributed to another storage for heating purpose (step 5).

-

-

-

In the following video, the process of simulation a hydraulic system is briefly described:

(Source: JER)

-

-

-

For this exercise, you need to download the Excel file below: HyCool_System simulation exercise - latent heat storage.

This simulation exercise gives a basic knowledge of the differences between sensible and latent heat storages.

-

For this exercise, you need to download the Excel file below: HyCool_System simulation exercise - solar cooling, part A.

This exercise will provide a basic knowledge on the methodology of dynamic simulations. The exercise focuses on 24 hours of one day and an exemplary solar irradiance and the generation of cooling power through a thermal chiller.

-

For this exercise, you need to download the Excel file below: HyCool_System simulation exercise - solar cooling, part B.

This exercise will deepen your knowledge on simulation process, especially taking account the charging and discharging of storages.

-

-

-

The EU-funded project HyCool focuses on piloting innovative cooling systems both in food and chemical industry. The performance and feasibility of an innovative solar cooling system is heavily dependent on the local climate conditions. For this purpose, the partners in the HyCool, namely R2M, JER, Ekodenge and COMET, developed the HyCool Pre-feasibility tool.

This tool enables users to evaluate whether or not HyCool technology is suitable for a given industrial cooling process.

The HyCool Pre-feasibility tool offers a first evaluation of feasibility, based on

- local climate (annual solar irradiation, annual average ambient temperature)

- technical information (industrial process temperature, annual full load operation hours)

- economic aspects (electricity price)

Check it out and click the Link:

HyCool Pre-feasibility simulator

- local climate (annual solar irradiation, annual average ambient temperature)

-

-

-

The EU-funded project HyCool focuses on piloting innovative cooling systems both in food and chemical industry. This system is based on the application of a hybrid chiller, making use of both compression and adsorption chiller. The performance of such an adsorption chiller is heavily dependent on following temperatures:

- Inlet temperature of the hot water in the adsorption chiller (HT)

- Inlet temperature of the re-cooling water in the adsorption chiller (MT)

- Outlet temperature of the chilled water/glycol solution from the compression chiller (LT)

The HyCool Performance calculator tool is apt to predict the refrigeration capacity and energy efficiency ratio (EER) of the cascade HyCool chiller for a given industrial cooling process.Check it out and click the Link:

- Inlet temperature of the hot water in the adsorption chiller (HT)

-