Solar Heating and Cooling System Overview

Abschnittsübersicht

-

-

HyCool uses a concentrating technology based on ECOTHERM’s novel Fresnel collectors. It has been specifically designed to offer a compact and easy-to-install system to ensure successful small-scale installations. As you can see in the picture below, the system is based on flat mirror modules, which consist of narrow stripes of tempered glass glued directly onto silicon line hinges. Detailed information on this technology is provided in our eLearning training course Fresnel Solar Collector.

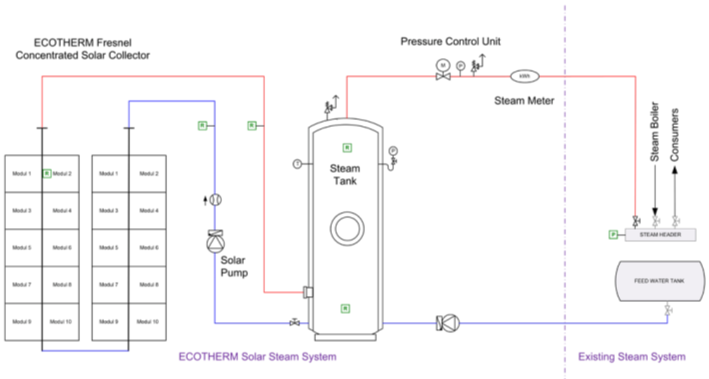

The whole solar system as shown in the picture below (main part of the schema) consists of the above mentioned Fresnel Solar Collectors, a Solar Pump, a Steam Tank and a Pressure Control Unit. The system operates at pressures between 0 and 25 bar, generating steam amounting from 0,3 and 10 t/h. The HyCool Solar System that counts with triple safety devices operates fully automated and is observed via remote monitoring. The system integration requires no changes in the existing steam system which is very beneficial for the operators of industrial sites applying HyCool. The design lifespan is estimated to 25 years.

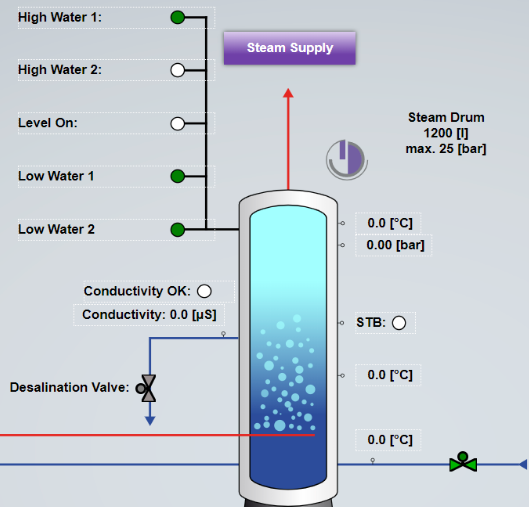

The steam drum is the heart between steam generation and steam consumption in Hycool. Its function is to separate the steam/water mixture that we receive from the solar thermal collectors. The steam will be collected in the top of the steam drum and from there supplied to pressure reducing stations before being consumed by the factory. Non-evaporated condensate is mixed with the remaining feedwater in the bottom of the tank to be pumped again through the solar field. It is TUV approved and operates at pressures of 25 bar. Since solar irradiation is changing due to weather conditions and the natural course of the sun, the steam drum balances the resulting control fluctuations between energy supply and consumption. The pressure balancing avoids steam hammering and increases the material lifespan.

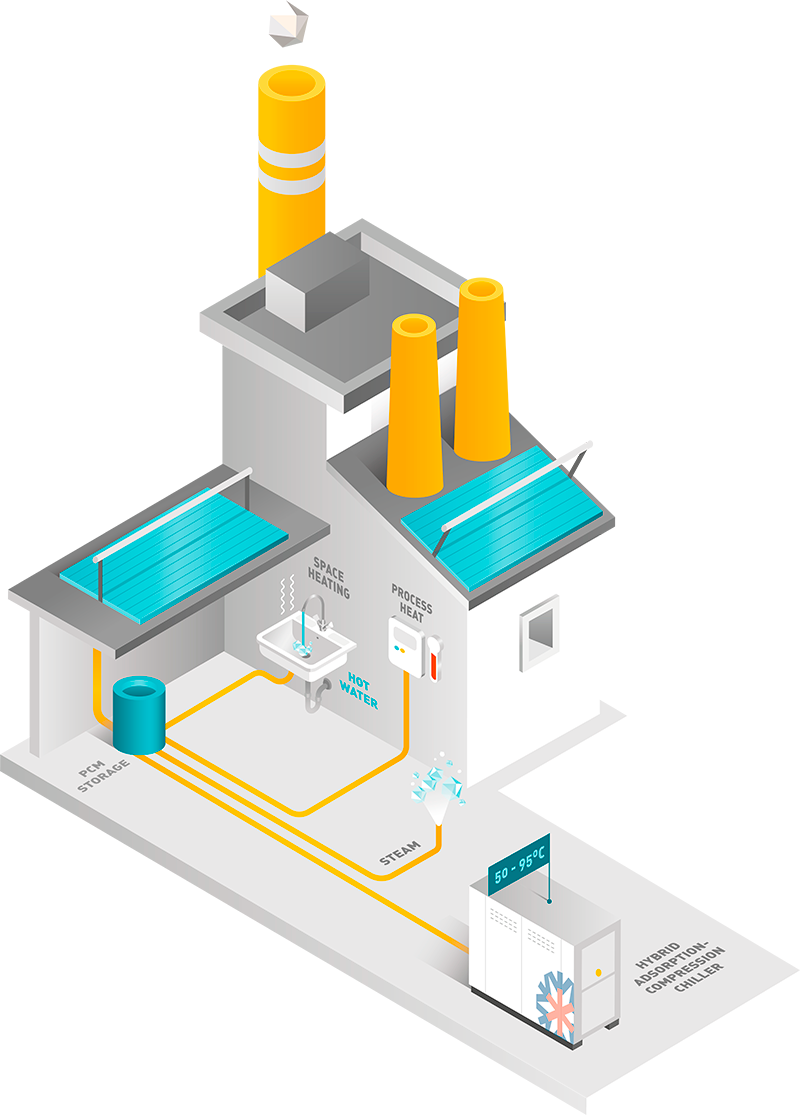

The hybrid adsorption-compression chiller used within HyCool allows a step forward towards the exploitation of thermally driven cooling systems in industrial applications. The hybrid adsorption-compression chiller is thermally driven and provides cold out of heat. It exploits both thermal energy (either from waste heat or renewable sources) and electrical energy to deliver cooling energy at high electrical efficiency. The combination of these two technologies allows to cover the cooling load regardless of the current availability of solar heat thus ensuring an ongoing, safe and efficient cooling of industrial processes. Tests of the Cascade chiller showed chilled brine temperatures between +20°C and -16°C. Reliable operation under design and off-design conditions were observed. The cooling power ranges between 22 kW and 7kW and EER values up to 40% higher than standard solutions (R134a chillers) were achieved. Detailed information on this technology is provided in our eLearning training course Hybrid Heat Pump.

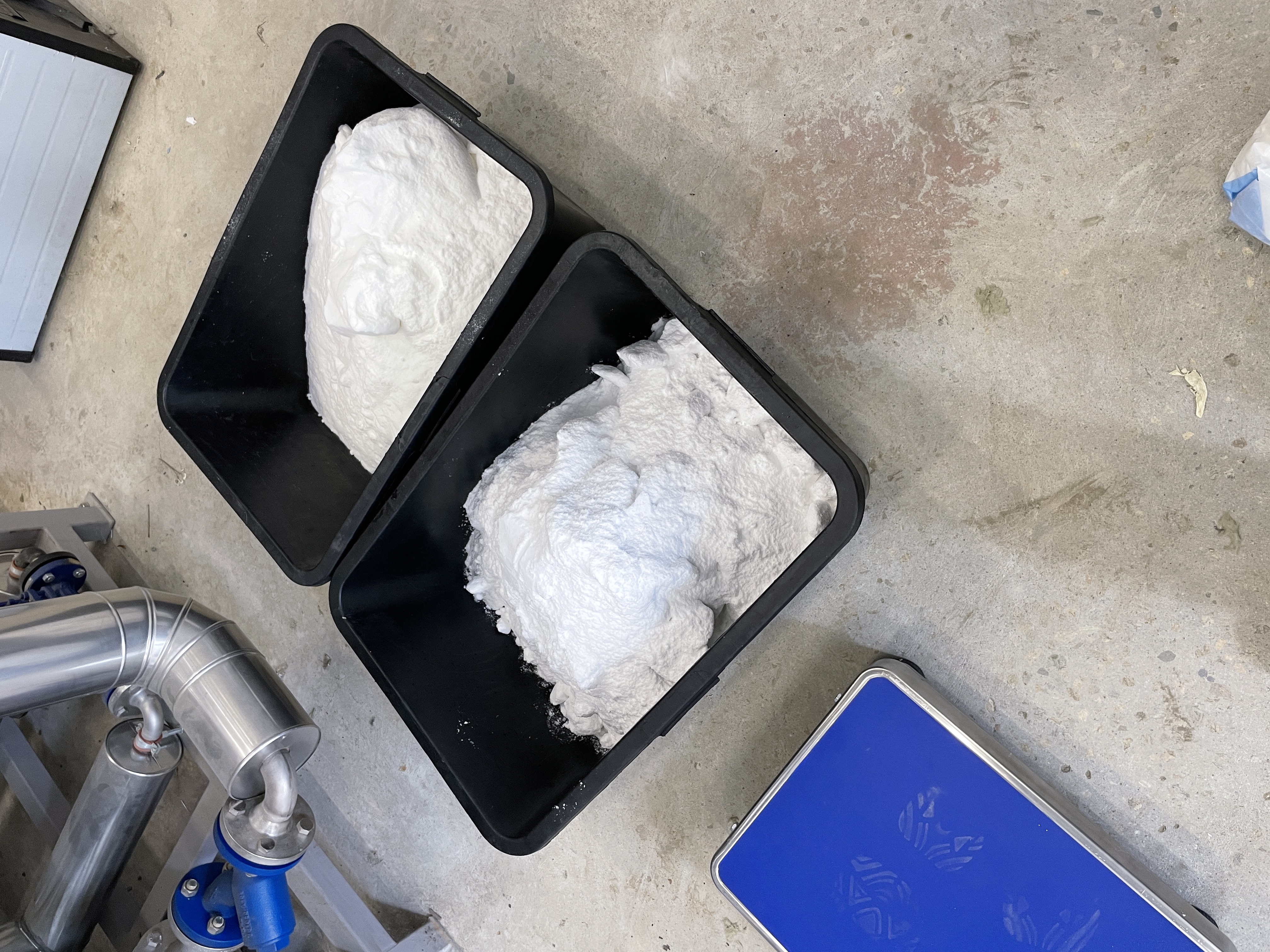

Polymers and nitrate salts are widely available, cheap and versatile classes of material that can be used as Phase Change Materials (PCM). Many polymers can be produced of renewable biological sources and the professional recycling industry allows for sustainability. PCM storages can be used in many different applications with very different requirements in terms of storage capacity, charging and discharging power profiles, available charging inlet temperatures and demanded discharging outlet temperatures. Detailed information on this technology is provided in our eLearning training course Latent Heat Storage.

-

-

-

In this presentation R2M explanes HyCool's Exploitation path under Horizon 2020.

-

-

-

Welcome to our quiz about Latent Heat Storage. This quiz requires a subscription (free user account) to the e-Learning platform www.waermepumpe-weiterbildung.at and full access to this course.

Click here to get your free user account and free full access to all our free courses.

Instructions:

- The quiz is a multiple-choice test, e.a. either one or more of four possible answers is correct.

- No points are deducted for incorrectly answered questions.

- You can get immediate feedback on whether your answer is (partly) correct or not by clicking on the "Check" button.

- To proceed from one question to the next, click on the "Next page" button.

- The time is limited to ten minutes, after which time the quiz is closed and scored automatically.

- After finishing, click on the "Finish attempt ..."-button and then on the "Submit all and finish" button.

- Then, you get a review of all questions including the right answers as well as your Grade and Feedback.

- Don't worry, if your Grade is not the best. You can try the quiz as often as you want and improve from try to try.

Tip: If you have problems with one question, answer the other questions first. If you still have time at the end, you can return to the unclear questions via the Quiz navigation box on the right side.

- The quiz is a multiple-choice test, e.a. either one or more of four possible answers is correct.

-