Latent Heat Storage

Abschnittsübersicht

-

-

The project partner AIT Austrian Institute of Technology was responsible to develop and provide a latent heat storage at the demo site of Bo De Debo.

The storage is used to store solar energy produced by the Fresnel solar collector field. This is necessary for achieving high solar fractions as there is no solar energy available during night, in bad weather conditions and furthermore in short supply in the morning and evening.

To charge the storage pressurized water is used as heat transfer fluid and enters the storage at temperatures up to ~135 °C. When discharging the storage, water with ~90 °C has to be heated up to 110-120 °C.

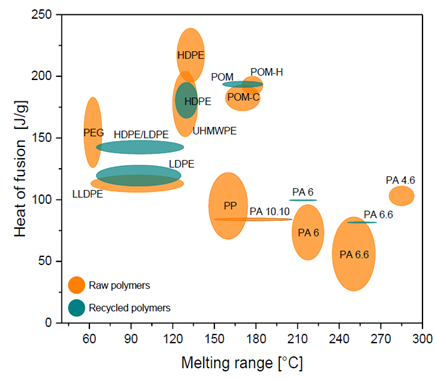

Thus, a suitable phase change temperature is around 125 °C, which is exactly met by a polymeric phase change material that has been studied by AIT in the last years thoroughly: high density polyethylene. -

Within the Austrian reserach project StoreITup-IF, it was successfully demonstrated that polymers are a class of materials that are very well suited to be used in latent heat storages as phase change material.

Many details can be found in the final report as well as in dedicated publications listed in the final report available from the project web site:

https://www.ait.ac.at/en/research-topics/sustainable-thermal-energy-systems/projects/storeitup-if/

Polymers have various advantages, which make them very interesting as PCM:

- Different polymers types are produced on a large industrial scale worldwide in standardized qualities.

- Polymers are relatively cheap. Some grades cost less than 1 €/kg.

- A mature recycling industry is in place. It was shown within StoreITup-IF that recycled polymers are perfectly suitable as PCM, but even cheaper than new ones.

- Polymers can be compounded with many different additives to tune their thermophysical, electrical and rheological properties.

-

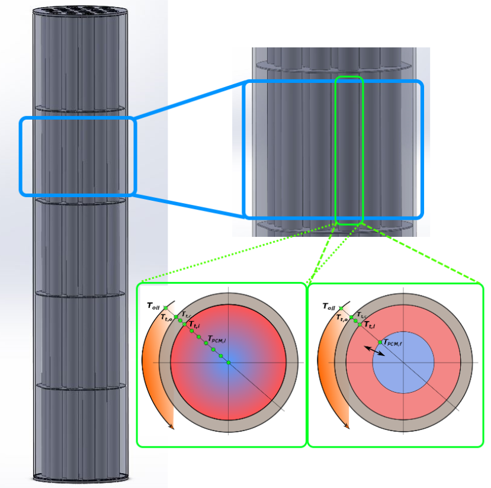

In addition to the PCM, the second key component of a latent heat storage is the heat exchanger, which transfers heat from a heat transfer medium to the storage material (and vice versa).

Different heat exchanger concepts are possible and have been investigated in literature. In HyCool, we make use of two concepts investigated and developed at AIT for several years. Information on many technical details can be found in the corresponding publications.

- fin-tube heat exchanger: http://dx.doi.org/10.1016/j.apenergy.2016.06.138

- inverted shell and tube heat exchanger: http://dx.doi.org/10.1016/j.apenergy.2016.12.079

- fin-tube heat exchanger: http://dx.doi.org/10.1016/j.apenergy.2016.06.138

-

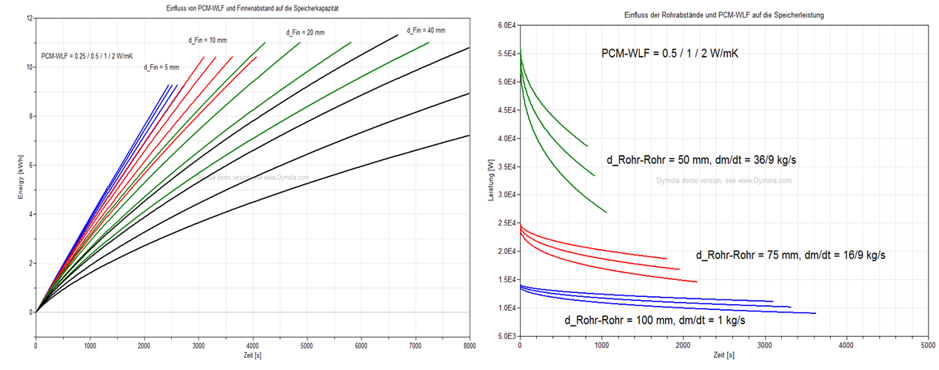

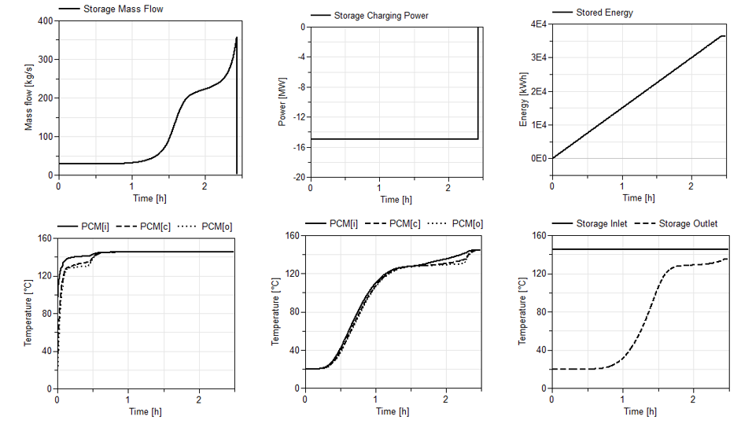

In order to be able to design a latent heat storage in terms of energy capacity and charging and discharging power, a dedicated computer model was developed at AIT. The melting and crystallization of the PCM is simulated within the storage and all relevant modes of heat transfer are included.

The model was implemented in Dymola using Modelica language. It can be used for parametric studies to design the geometry of a latent heat storage exactly suitable for a specific application.

In addition, the latent heat storage model can be integrated into any HVAC system and also be used to develop appropriate control strategies.

-

-

-

The HyCool pilot site for the food industry Bo de Debò is preparing precooked fresh dishes based on meat, fish, and vegetable products. Industrial cooling installations are necessary for the good preservation of the product. The cooling installations extract heat from different rooms to achieve the the required temperatures in the chamber.

-

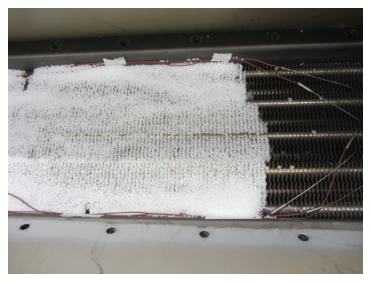

The most suitable heat exchanger design for the demo site of Bo De Debo was found to be a fin-tube heat exchanger. The high density polyethylene is poured into the storage on site similar to what was previously done at the storage lab at AIT:

-

-

-

The Latent Heat Storage at the Demo Site Givaudan can be seen in this picture.

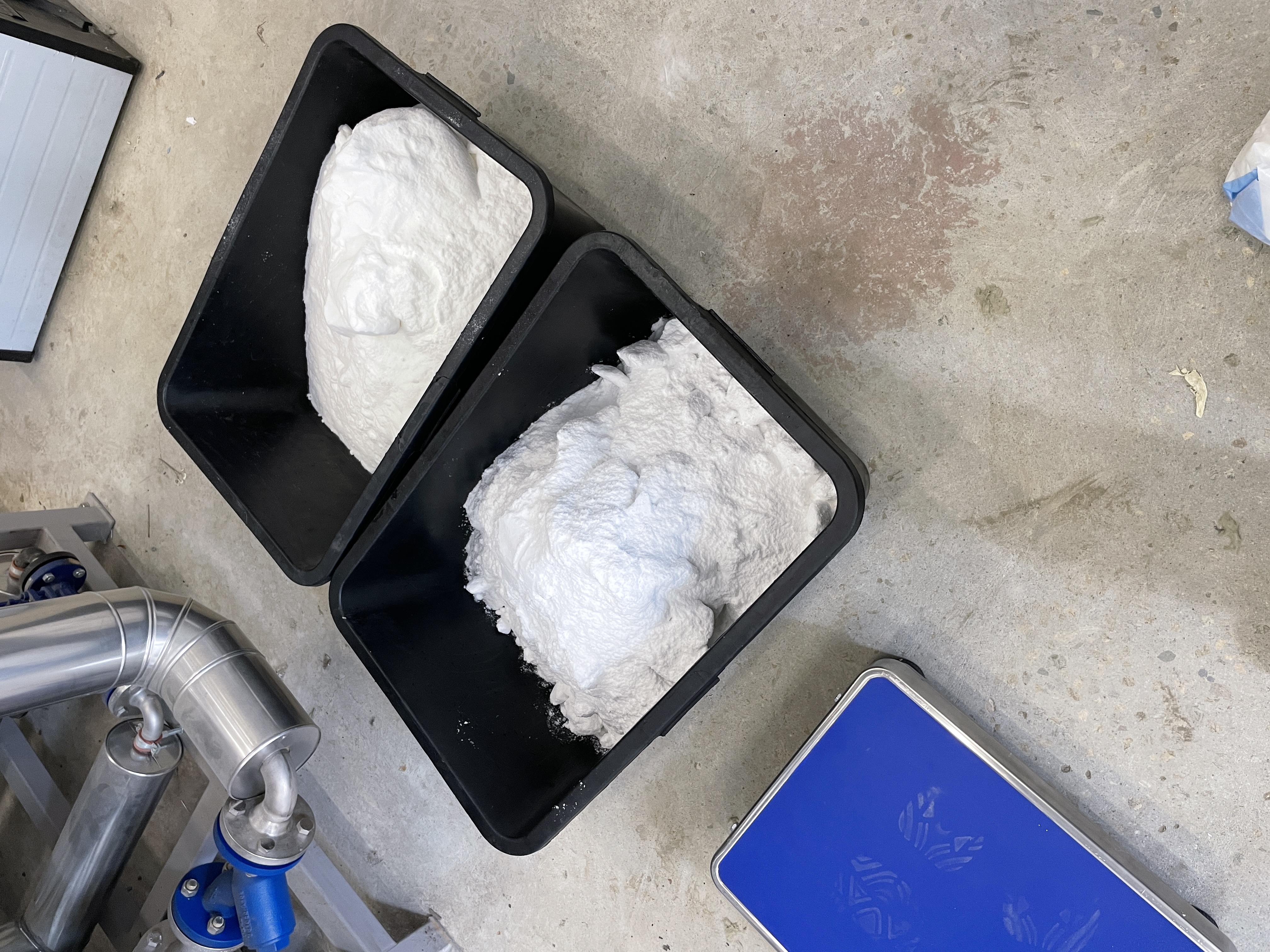

The PCM material (nitrate salt) filled into the Latent Heat Storage is shown in the picture below.

-

-

-

Welcome to our quiz about Latent Heat Storage. This quiz requires a subscription (free user account) to the e-Learning platform www.waermepumpe-weiterbildung.at and full access to this course.

Click here to get your free user account and free full access to all our free courses.

Instructions:

- The quiz is a multiple-choice test, e.a. either one or more of four possible answers is correct.

- No points are deducted for incorrectly answered questions.

- You can get immediate feedback on whether your answer is (partly) correct or not by clicking on the "Check" button.

- To proceed from one question to the next, click on the "Next page" button.

- The time is limited to ten minutes, after which time the quiz is closed and scored automatically.

- After finishing, click on the "Finish attempt ..."-button and then on the "Submit all and finish" button.

- Then, you get a review of all questions including the right answers as well as your Grade and Feedback.

- Don't worry, if your Grade is not the best. You can try the quiz as often as you want and improve from try to try.

Tip: If you have problems with one question, answer the other questions first. If you still have time at the end, you can return to the unclear questions via the Quiz navigation box on the right side.

- The quiz is a multiple-choice test, e.a. either one or more of four possible answers is correct.

-